Greetings, I like this site and I like hardwood floors. My 1950s house is 80% hardwood floor, and soon to be 100% (at least at grade!). From identifying marks on the boards, I have Clear Grade Appalachian White Oak. 2 1/4" x 3/4" so fairly standard stuff.

Here's my project: I knocked out 2 walls between what were my living room, dining room and foyer and now have one large 24'x12' room that opens perpendicular to the kitchen. There is a 9x9 area that had no hardwood

The room:

I started putting in the underlayment extensions and then cut down the extended areas. Fortunately this provided me samples I took to the local hardwood flooring warehouse.

The underlayment (that will be removed)

I originally figured it would be impossible to match the hardwood, so I was going to put Duraceramic in place. While I was preparing subfloor pulling the existing hardwood planks preparing for the underlayment, I was able to identify the wood and grade used based on the information printed under the planks!

So now it totally changed my game plan, I would much rather use hardwood in the whole room and also the kitchen. I took a few samples to a local hardwood floor wholesaler/supplier and they had Select or Better white oak in stock from Middle Tennessee Lumber. Lumber Liquidators had Select grade white oak too but the lengths were 1-7' where the other flooring is longer and better match the longer planks of my house. The unfinished "select or better" grade costs a little less than duraceramic too.

My plan now is, I want to stagger the existing floor with the newer unfinished white oak, then have the entire room (possibly the entire house) professionally sanded and restained. I'd cut out the existing planks at random lengths so it doesn't look like the hard line it has now. I would hope with this approach it should match reasonably well. Fortunately the tongues are pointing towards the unfinished part so at least they are going the right direction

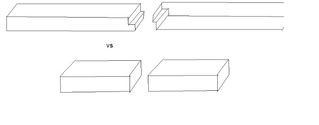

my question now- when doing the joints between the existing floor and the newer floor- can I just butt joint them? Or should I try to router/chisel out the top and the bottom to create interlocking joint? I'd imagine trying to recreate the tongue groove on an installed floor would be fairly tricky due to the rounded edge of the router bit and the potential of runining the adjacent boards (not to mention a flooring T&G bit set is over $100 like the grizzly C2307).

Drawing of what I mean: